- Home

- About

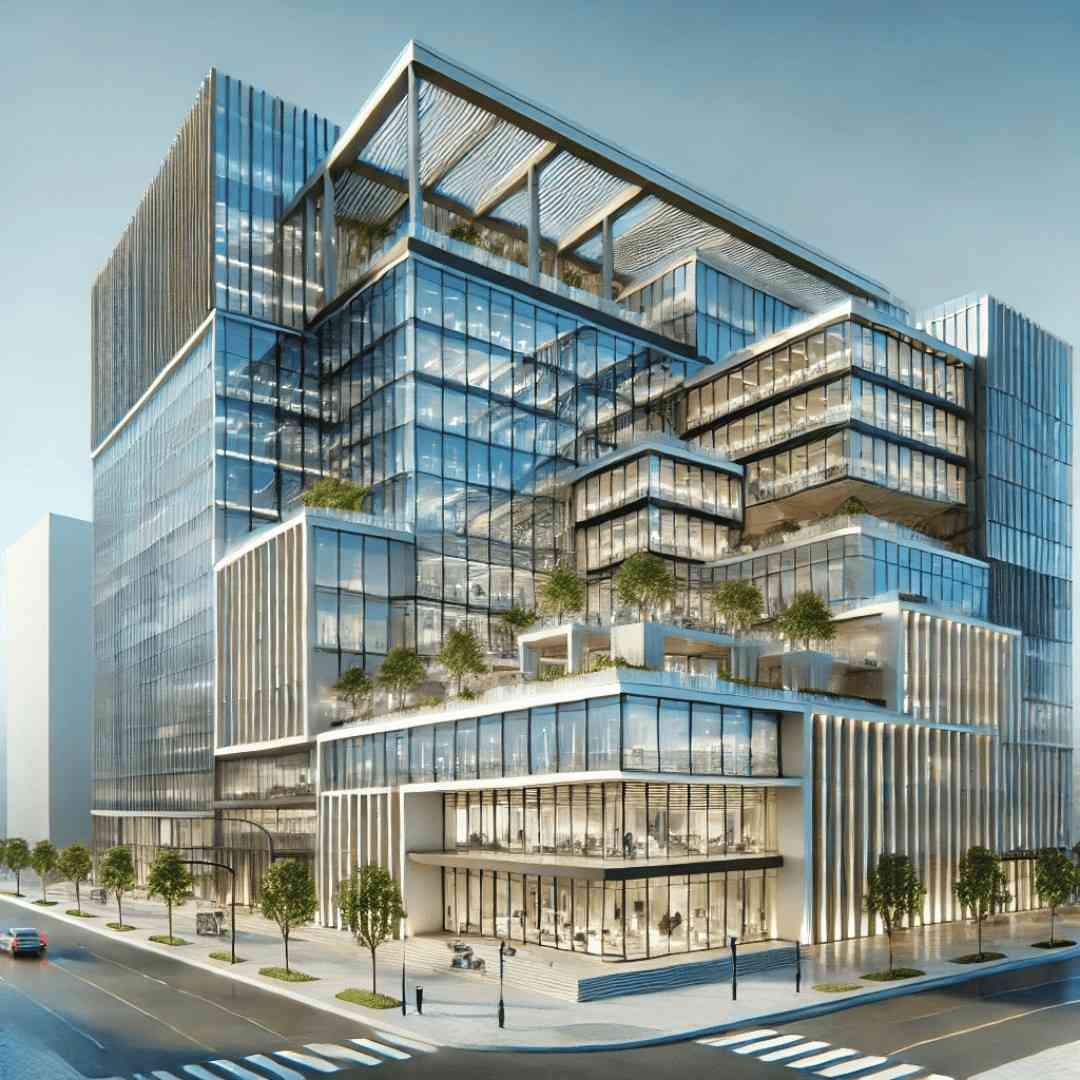

- Real Estate

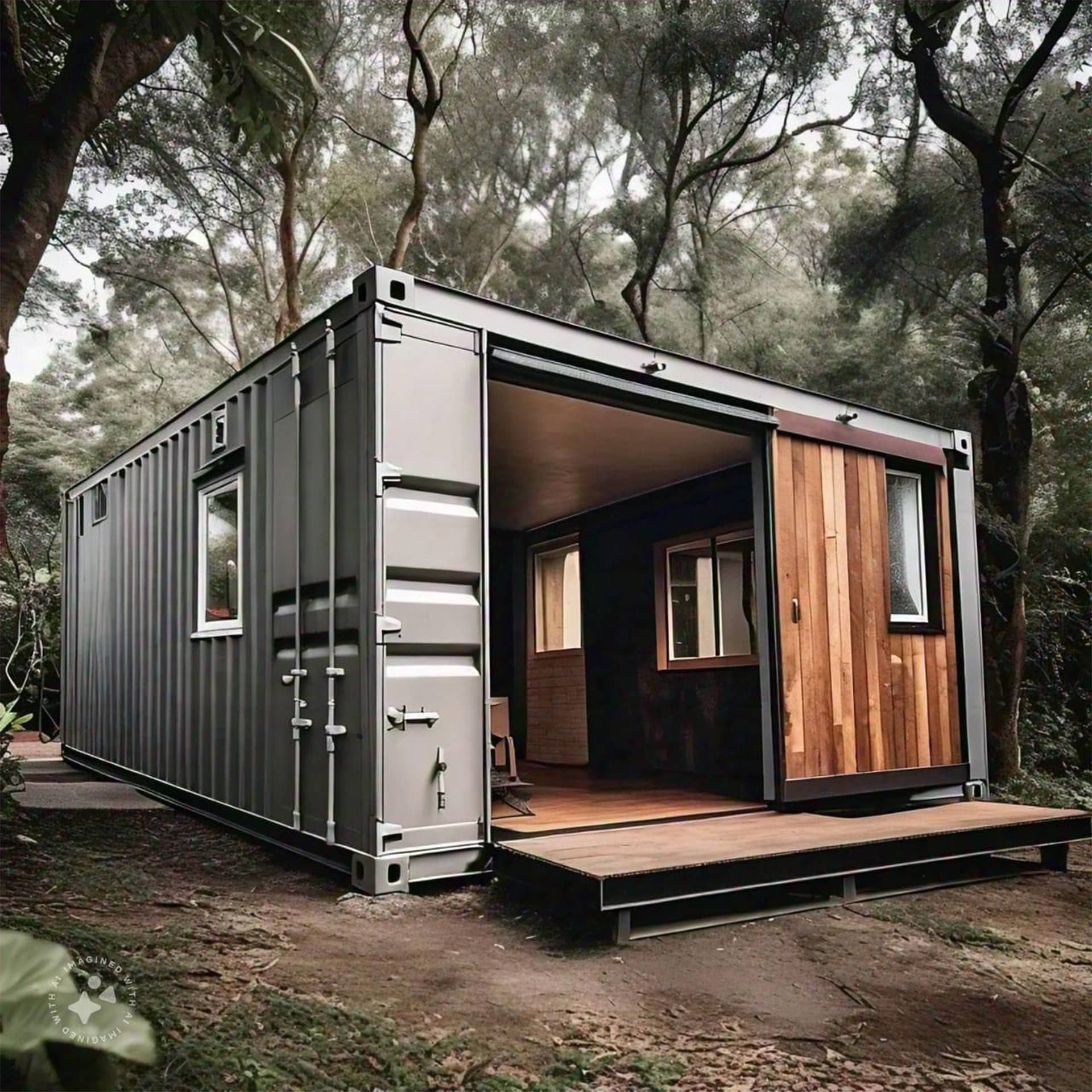

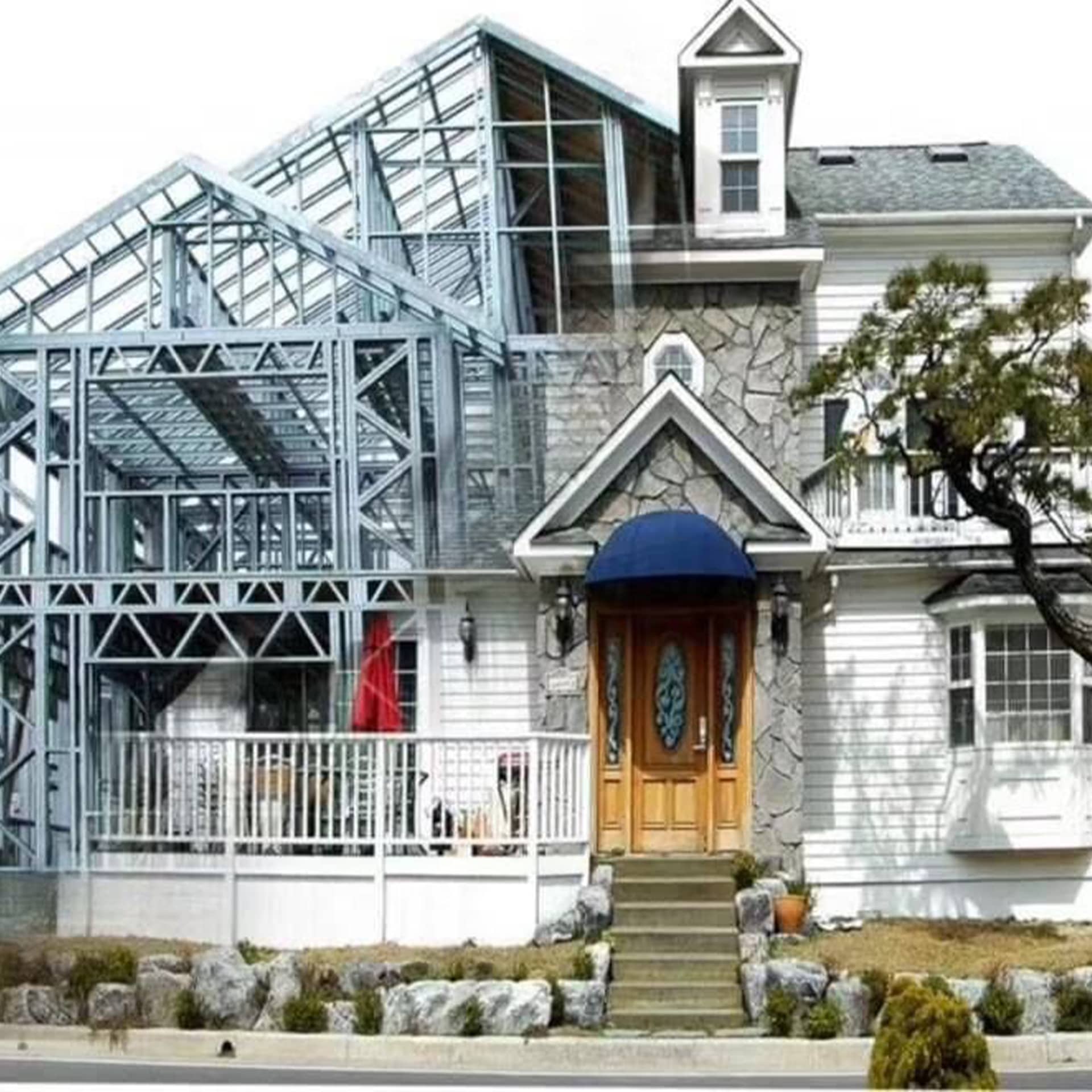

- PreFab

- Agribusiness

-

Facility Management

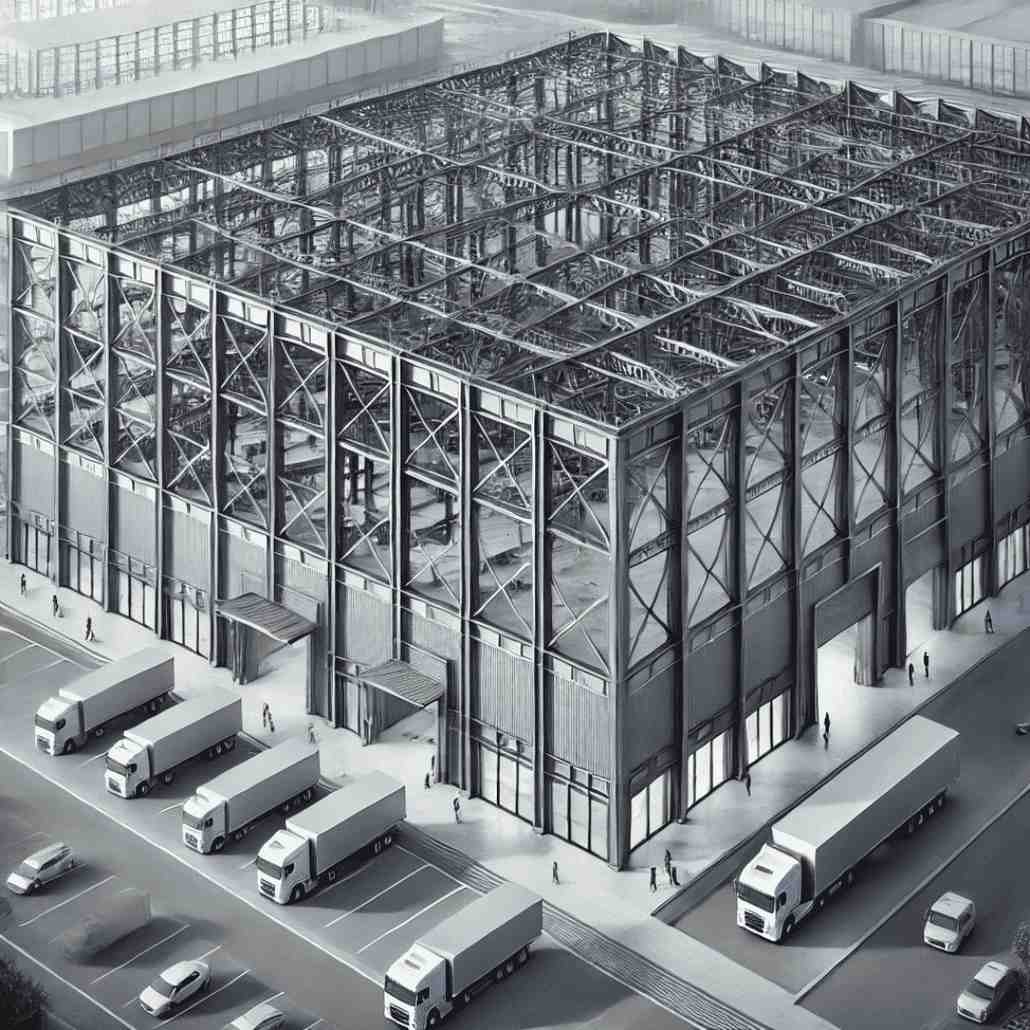

- Facility Management

- Overview

- Corporate & Workplace Management

- Security & Risk Management

- Housekeeping & Cleaning

- Technical Maintenance (Hard Services)

- Hospitality & Guest Experience

- Food & Pantry Services

- Landscape & Outdoor Management

- Waste, Environmental & Pest Management

- Industries We Serve

- Why XIPHIAS Facility Management

- Clients

- Project Management

- Skill Development

- Contact